-

First Lighting of the Forge & Antique Habaki Utsushi (写)

First lighting of the newly rebuilt charcoal forge in the island kajiba followed by stamping the tang and then hand forging and filing a classical tanto style habaki, silver soldered in the charcoal forge and closely based on an antique Edo period habaki. An utsushi (写) is a closely based study of another work for…

-

Furusato Tanto

Furusato (故郷, pronounced “foo-roo-sah-toe”) means home place or hometown and contains the ideas of being rooted or grounded wherever one may sojourn, and a confidence and longing for return. This tanto has a simple and elegant form with a natural and humble mounting that reflects the rustic satoyama lifestyle and suits the aesthetics of the…

-

SOTW #20 – Assembling the Furusato Tanto

This discarded block of wood from the Congo/Zaire sat for several years waiting for the right blade to make the best use of it. This precious dark chocolate coloured hardwood is locally called Tshikalakala or Dikela, meaning turn around or circle back, and this particular piece has a slightly curving grain that follows the line…

-

TLDW #24 – Making an Ireko (nesting) Saya

An ireko saya (入れ子鞘, nesting scabbard) is a lining inside the saya which protects the blade from the hardwood. Furusato (故郷) means home place or hometown and contains the ideas of being rooted or grounded wherever one may sojourn, and a confidence and longing for return. This tanto has a simple and elegant form with…

-

Inome Tanto

The inome (pronounced “ee-no-may”, 猪の目, eye of the boar) name comes from the pierced heart-shape designs of the decorative o-seppa (washers) on either side of the tsuba (handguard). This lovely motif is ubiquitous in Japan, seen often in architecture, furniture, and sword mountings. In this context, the inome symbol conveys the idea of the focused,…

-

SOTW #19 – Assembling the Inome Tanto

The inome (pronounced “ee-no-may”, 猪の目, eye of the boar) name comes from the pierced heart-shape designs of the decorative o-seppa on either side of the tsuba. This lovely motif is ubiquitous in Japan, seen often in architecture, furniture, and sword mountings. This is the first of my blades to incorporate antique sword parts as part…

-

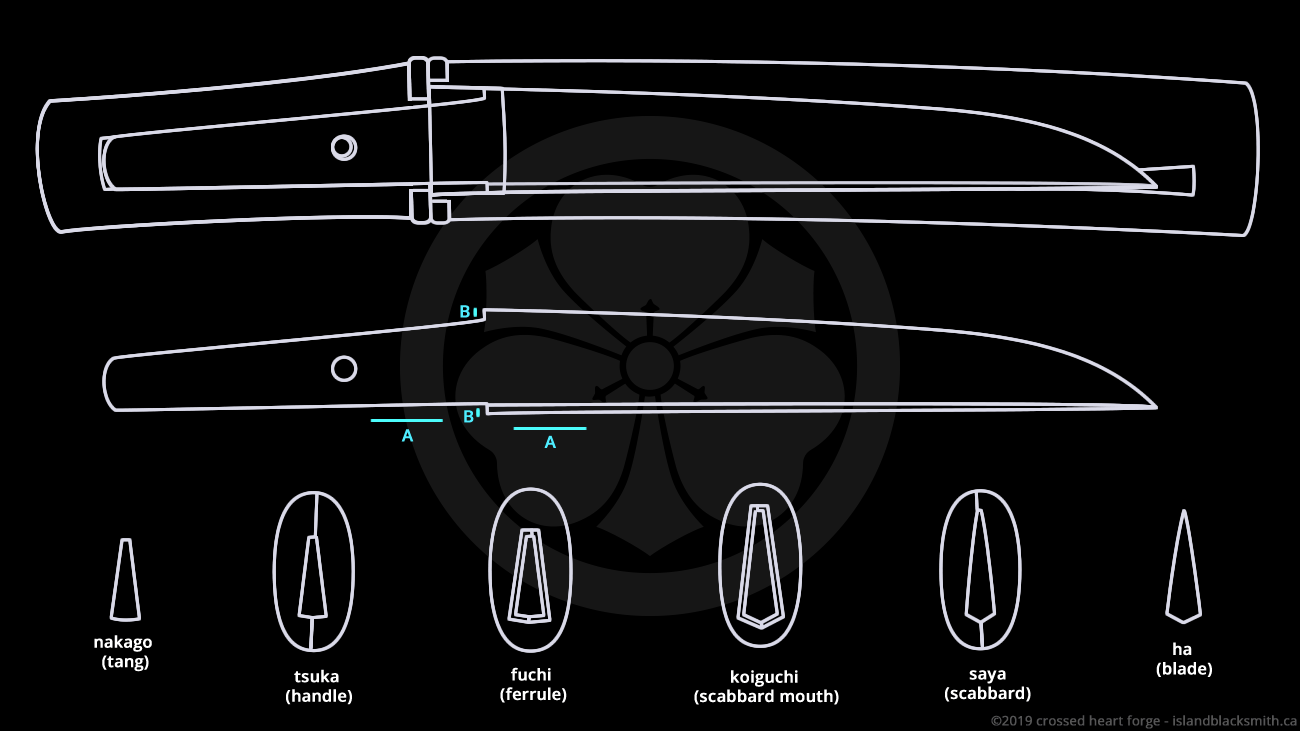

Eyes on the Spine: say No to the kink, and Yes to the flow

One of the most common mistakes when attempting to recreate a Japanese classical style tanto is to caricature or over exaggerate certain design elements while entirely missing others. The Japanese aesthetic is subtle and nuanced, millimeter differences can make or break the lines of a blade or koshirae. A subtle curve is almost always more…

-

Keeping it Simple with Paracord

This special project commemorates a milestone for a long term friend and supporter of the forge and represents another variation of the fusion style outdoor knife genre. The concept is the combination of a western bowie shape made with Japanese techniques, the simplicity and durability of a solid integral cord wrapped handle, and a nata…

-

Yoroidoshi in Shirasaya

This blade began as a segment of reclaimed horse-drawn carriage spring and was hand forged in a charcoal fire, smoothed with files and a sen scraper, hardened using traditional water quench yaki-ire, and polished by hand with natural Japanese water stones. Crafted and finished entirely with hand tools and traditional techniques, the slender blade profile…

-

Arashiage: Filing Order of Operations

Arashiage is the stage of rough shaping following hizukuri (forging) and in preparation for yaki-ire (hardening). Earlier posts have described tanto kata and the geometry of the tang, machi, blade, and kissaki. Familiarity with these geometry points is a prerequisite to success in this stage. This post will illustrate the proper order of operations for…

-

Utsushi Study of a Sunnobi Tanto

Sunnobi tanto (寸延び短刀) are larger than ordinary tanto, with nagasa a sun or two above 1 shaku (sun nobi, “a sun longer”, from nobiru, to stretch or lengthen). Though there is some area of crossover with hira-zukuri ko-wakizashi and they may have sori similar to ko-wakizashi, the simplified difference would be that they are still…

-

Differential Hardening Sunnobi Tanto

Sunnobi tanto are larger than ordinary tanto (nagasa above 1 shaku) and may have sori similar to ko-wakizashi. Read more about the process of yaki-ire. 1. Using approximately a 1:1:1 mixture of natural clay, polishing stone powder and ground charcoal to mask the back of a hand forged blade about 1-1.5mm thick to slow down…

-

Process – Making habaki with simple tools

Making a habaki from reclaimed copper. Material is scrap copper from an electrical bus bar, forged and bent to shape, silver brazed with hard silver solder in the charcoal forge with fuigo, finish work done with files and rasps. Watch the shorter overview edit here.

-

Yakiire – Traditional Clay & Water Quench

The immersive experience of being in the darkened workshop during a traditional clay and water quench using a charcoal forge. A hamon is created on a tanto using a 1mm thick layer of roughly 1:1:1 natural clay, charcoal powder, and polishing stone powder. The blade is about 29cm long (nagasa), 2.3cm wide (motohaba) and 6mm…

-

温故知新・On Ko Chi Shin

A true and accurate understanding of the past is an important step towards a good future. 温故知新 (on ko chi shin) is an expression that most directly translates to, “study the old to know the new”. This one-of-a-kind project represents the current progression of my work based on the study and practice of historical techniques,…