-

2011-2020 Portfolio: A Decade in Review

This newly released documentary book project is the result of many weeks of editing and design work and can be enjoyed by the collector, enthusiast, and craftsman alike. It contains over 200 photos and highlights more than 30 knives spanning the past decade of work at Crossed Heart Forge since relocating from Japan in 2011.…

-

Simple Bladesmithing Anvil

Traditional Japanese swordsmithing anvils are simple in form and can be made from readily available materials. This article will present a photographic overview of the process of removing and replacing the swordsmith’s anvil at the museum forge on Vancouver Island. Most of history was forged with very simple equipment made from found and natural materials.…

-

Nagatsuki Tanto

Nagatsuki (長月, pronounced “nah-gah-tsoo-key”) translates literally as “long moon”. In the ancient calendar it is a poetic name for the time around late September, possibly abbreviated from yonagatsuki meaning “night of the long moon”, or “month of the long night” depending on the reading. The idea is associated with the time of Autumn, seasonal change…

-

Museum Forge Update

Traditional Japanese swordsmithing forges can be constructed with simple materials and natural ingredients. This article will present a photographic overview of the process of refurbishing the swordsmith’s forge at a museum on Vancouver Island. Most of history was forged with very simple equipment made from found and natural materials. A basic charcoal forge can be…

-

The End of an Era

It is with some hesitation and a great degree of uncertainty that I interrupt the usual flow of news to bring you this official announcement of the end of an era. While we were blessed to have a workspace on the same property for several years, the recent kajiba project came to a close much…

-

Island Forge: An Inside Look at Earthen Walls

An interesting opportunity to study the internal workings of tsuchikabe wall construction as the island kajiba series of photo essays comes to a conclusion, documenting the preparation, construction, and set up of a simple swordsmith style kajiba (鍛冶場, forge building) from the ground up. The main inspiration for aesthetic, form, and technique is the humble…

-

Island Forge: Kajiba Clean Up

Some views of the building in its tidiest state ever as the island kajiba series of photo essays comes to a conclusion, documenting the preparation, construction, and set up of a simple swordsmith style kajiba (鍛冶場, forge building) from the ground up. The main inspiration for aesthetic, form, and technique is the humble utilitarian Japanese…

-

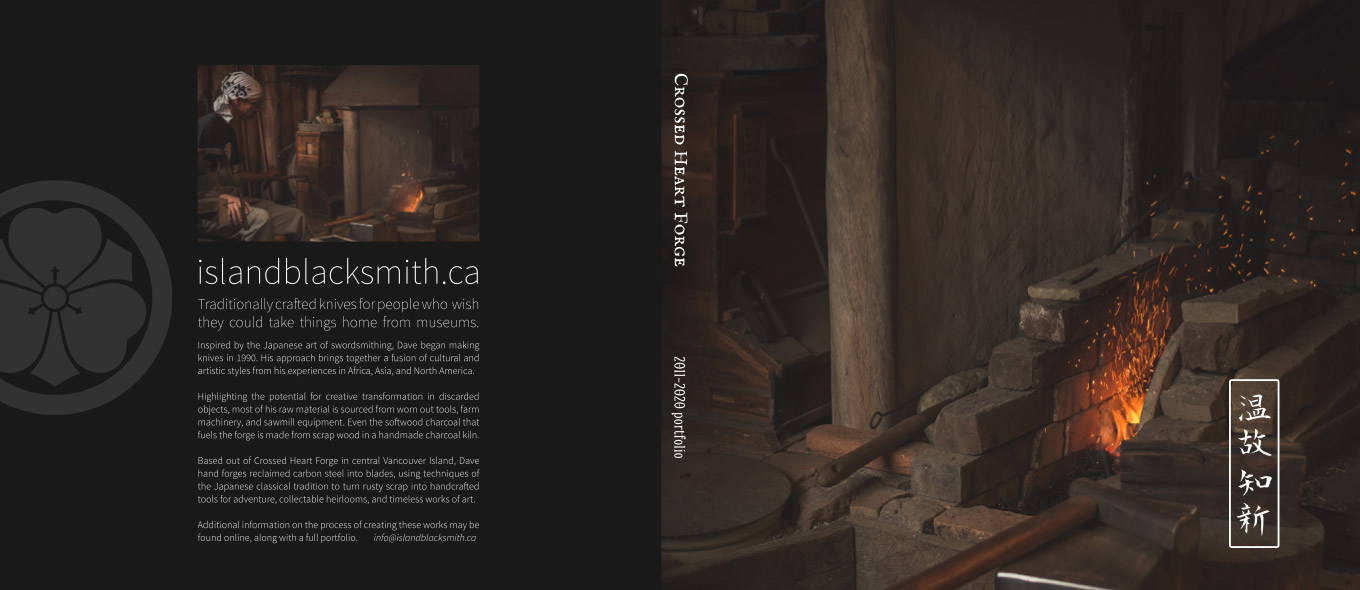

Photo Essay: Final Forging Day

Talented Vancouver Island photographer Jordan Wende stopped in at the Island Forge in mid-July to document the final forging session. In this installment of the series, using the mukozuchi hammer to perform wakashinobe in preparation for forging sunobe. Photographed and edited by Jordan Wende Interior Views Heating a reclaimed steel billet in the charcoal forge.…

-

Photo Essay: Forge Visit

Talented Vancouver Island photographer Jordan Wende stopped in at the Island Forge in mid-July to document a visit by Tim of Reforged Ironworks during the time he was helping clean up the forge. In this installment of the series, views of the forge and environs while using the mukozuchi sledge hammers. Photographed and edited by…

-

Photo Essay: Forging a Knife

Talented Vancouver Island photographer Jordan Wende stopped in at the Island Forge in mid-July to document the atmosphere and some of the work going on. In this installment of the series, forging a small outdoor knife from an antique carriage spring. Photographed and edited by Jordan Wende Wakashinobe – Lengthening the Billet Rough drawing out…

-

Photo Essay: In the Forge

Talented Vancouver Island photographer Jordan Wende stopped in at the Island Forge in mid-July to document the atmosphere and some of the work going on. In this installment of the series, scenes of working at the charcoal forge and anvil. Photographed and edited by Jordan Wende Interior Views At the charcoal forge Operating the fuigo…

-

Photo Essay: Teaching & Instruction

Talented Vancouver Island photographer Jordan Wende stopped in at the Island Forge in mid-July to listen, learn, and document the atmosphere and some of the work going on. In this installment of the series, candid shots of teaching and instruction along with notes on some of the topics covered in this session. Photographed and edited…

-

Photo Essay: Views of the Kajiba

Talented Vancouver Island photographer Jordan Wende stopped in at the Island Forge in mid-July to document the atmosphere and some of the work going on. In this installment of the series, several views of the forge, tools, and building. Photographed and edited by Jordan Wende Interior Views Tezuchi hand hammer on the anvil and mukozuchi…

-

Photo Essay: Views of the Shiageba

Talented Vancouver Island photographer Jordan Wende stopped in at the Island Forge in mid-July to document the atmosphere and some of the work going on. In this installment of the series, several views of the shiageba at rest. Photographed and edited by Jordan Wende Polishing, Fittings, & Lacquering Togi oke (polishing bucket) after a long…

-

Kominka Forest Kotanto

The core of this project is a charcoal-forged blade, water quenched with clay and sharpened with waterstones, an outdoor knife that has the foundation of the Japanese sword but is finished in the simple and humble style of farming and foresting tools of centuries ago. Satoyama are the managed forest areas that border the cultivated…